COMPANY PROFILE

IKOI S.p.A. is a global leading company manufacturing plants, machines, technologies and engineering services on PMs metallurgy, casting, pyrometallurgy and physics separation of pure and alloyed Precious Metals.

Its headquarters is in San Zeno di Cassola, on the Venice area, but the firm is operating worldwide.

Thanks to over 40 years of experience in the PMs industry of our specialists, our company developed and owns numerous patents in this field.

IKOI’s Vision is to create a Safe, Efficient and Green way to Process Precious Metals and our Mission is to bring Innovative and Sustainable Technology to Precious Metal Processors. This is why following ESG – Environmental, Social and Governance principles become crucial for corporate sustainability.

Innovation is the key driver of our company, through the activities of our Research and Development department and the continuous collaborations with research Institutions and prestigious Universities, such as CNR Italian National Research Council, University of Padua, University of Roma Tor Vergata, RWTH Aachen University, and others International Research Centers.

Our patented continuous process equipment for Gold and Silver bars production, the FLAMELESS TUNNEL® (LBMA Approved), is now considered the industry standard worldwide and the innovative ALS – ACIDLESS SEPARATION® (patented) is shifting the paradigm of the industry for pre-refining and refining; we’ve also introduced the FCC – FLAMELESS CASTING CHAMBER®, a revolutionary system for big bars production such as 1000 Oz Ag and 400 Oz Au Good Delivery LBMA, 15 Kg SGE and other sizes.

Our staff includes engineers and metallurgical experts, professional sales representative and service technicians, to provide complete support, from sales to design, installation, training and after sales.

IKOI has more than 300 plants installed in more than 50 countries and our staff can provide support in 10 different languages.

IKOI maintains relations and business cooperation with Organizations and Associations leader in the investment precious metals field, such as: London Bullion Market Association (LBMA), Shanghai Gold Exchange (SGE), the World Gold Council (WGC), Bankers, Miners and other major financial and politic experts in the field.

PRODUCTS

Goldsmiths:

Static and Tilting melting machines – Furnaces for melting pure or alloyed precious metals. Our furnaces are used for: granules production, anodes production, bars or ingots production, pre-melting bath.

Casting granules and powder machines – Induction static and tilting melting furnace for manual granulating production of precious pure metals or alloys in graphite or clay graphite mixture crucible, with automatic temperature control. IKOI’s metallurgical process knowledge allows the selection of the most appropriate technology and crucible material for each application.

Continuous casting furnaces – Induction melting furnace for continuous casting of all the pure and alloyed karat and colours of gold and silver. Fitted with a single or double inductor, and one or more work heads for the production of wire, flat bars, tubes and other section on request. All our continuous casting furnaces have an updated microprocessor which can control, set up, memorize and print up to 99 different programs and they comply with Industry 4.0 standard.

Static annealing furnaces – Static electric furnaces for annealing precious metals items, such as watch cases, tubes, pipes, jewelry and silver items.

Wire & Strip continuous annealing – Electric furnaces for continuous annealing of precious metals wires and strips.

Belt furnaces – Conveyor belt electric furnaces for braze-welding or annealing of small metal parts, chains, tubes and plates.

Refining process:

ALS – Acidless Separation® can achieves silver and gold separation without any chemicals, with the capability to avoid any metal loss. This is a pre-refining equipment to remove silver and volatile elements from Au/Ag/Cu alloys using vacuum distillation technology. Then the alloy can be easily dissolved in the Aqua Regia process or using gold electrolysis.

Prime Refining Unit, based in IKOI’s ALS® technology, is the result of ten years of experience in metal vacuum distillation. This machine can achieve silver and gold separation without any chemicals, with the capability to avoid any metal loss. This is a pre-refining equipment to remove silver and volatile elements from Au/Ag/Cu alloys using vacuum distillation technology. Then the alloy can be easily dissolved in the Aqua Regia process or using gold electrolysis. This plant is specifically designed for small and medium refiners who need flexible, fast and sustainable way to process a variety of feedstocks. The furnace is fully complied with Industry 4.0 standard.

Bars production process:

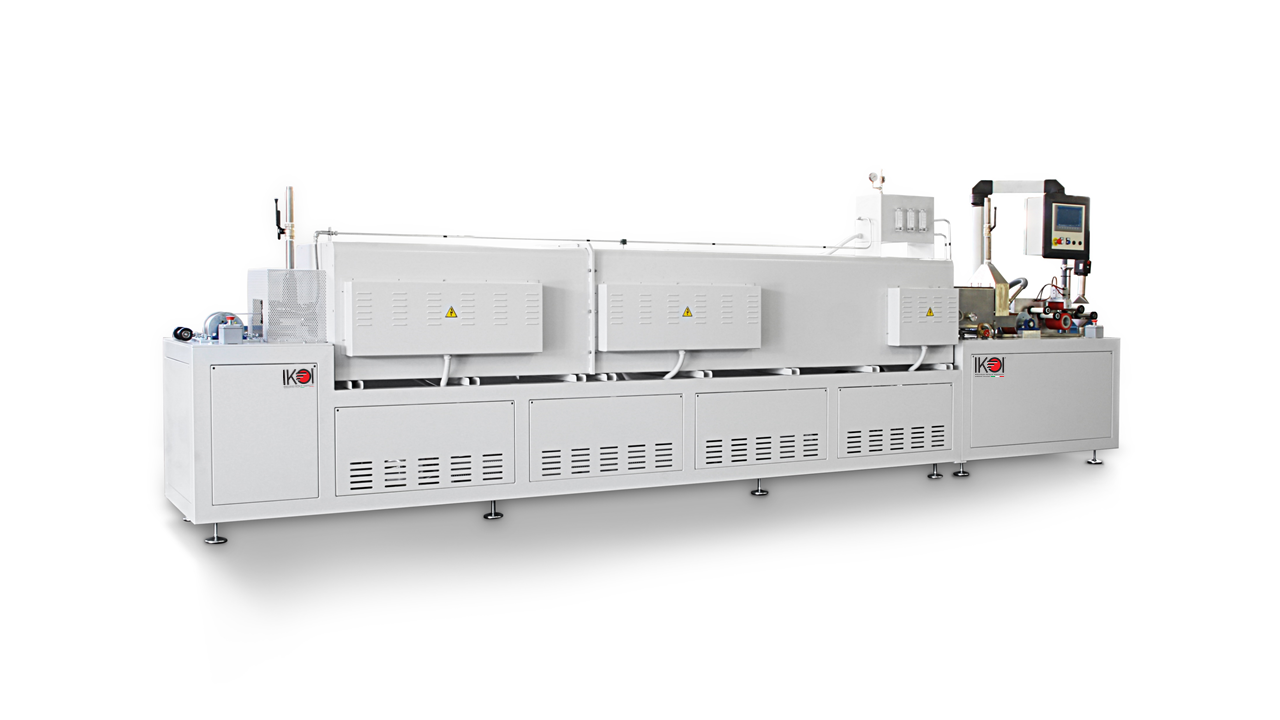

Flameless Tunnel® is the worldwide patented and LBMA approved casting system for the production of casted bars and Good Delivery bars of 400 Oz Au and 1000 Oz Ag. There’s not fumes, smokes, heat emission or precious metal losses, that allow it to be a “Green” technology and to comply with Industry 4.0 standard.

Dosing-Weighing machines allows high accuracy automatic dosing and weighing of gold and silver grains with advanced self-learning capabilities to achieve constant precision.

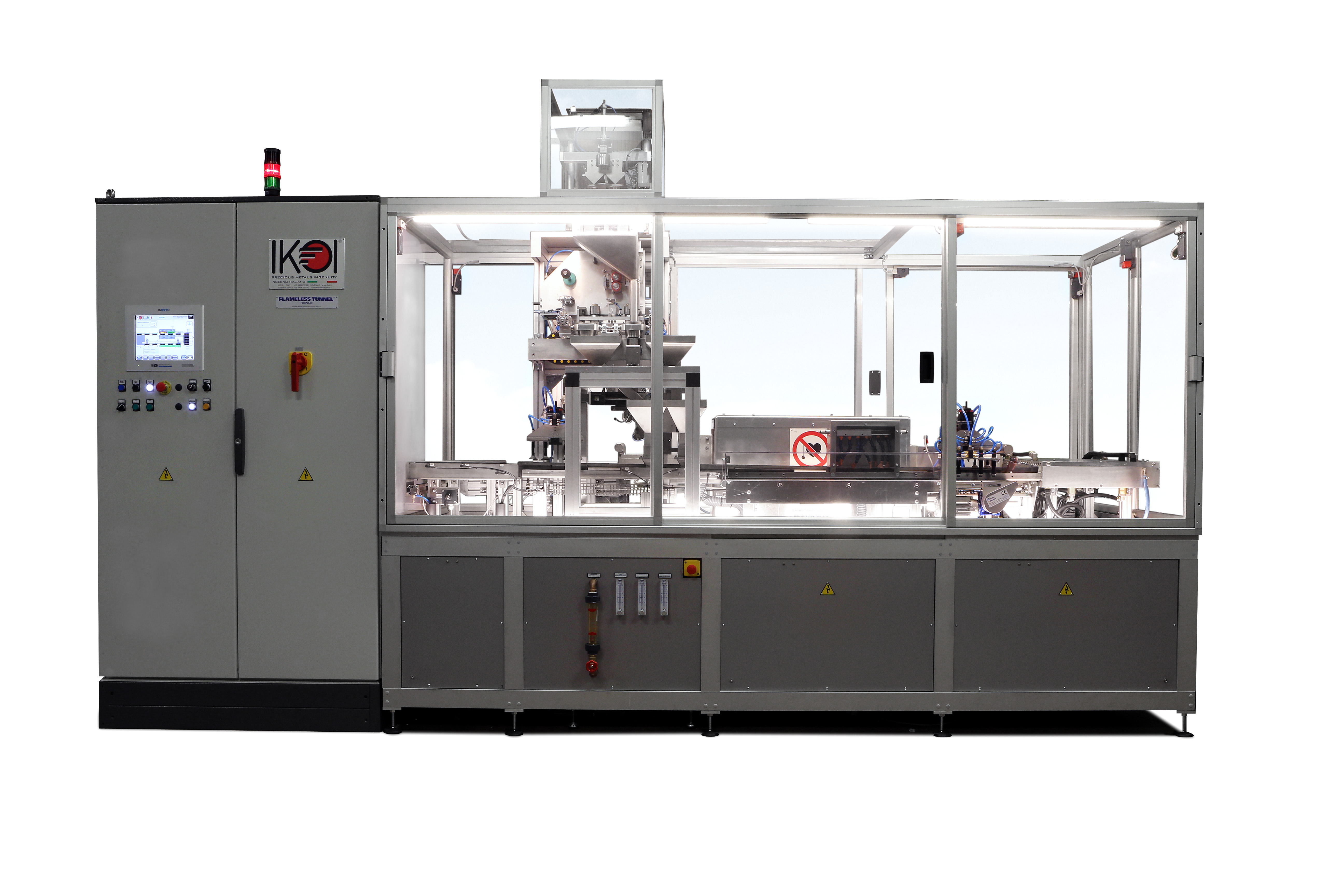

Compact is the perfect combination of advanced automation, accurate weighing, dosing system and Flameless Tunnel® technology to produce cast bars from 50 grams up to 100 Oz; the complete solution allows the completely automatic production of bars starting from silver and gold grains and the high accuracy automatic dosing and weighing of them, with an advanced self-learning capabilities to achieve constant precision (our Dosing-Weighing machines), everything complying with Industry 4.0 standard. The only necessary intervention by the operator is the filling of a hopper on the ground, connected to the vacuum suction system.

FCC – Flameless Casting Chamber® represents an unprecedented technological leap offering our customers higher productivity, higher safety and high sustainability. This is the evolution of our long-time know-how in casting technology: thanks to the experience of more than one-hundred Flameless Tunnel® furnaces installations, IKOI S.p.A. developed a revolutionary system specifically designed for Good Delivery and SGE bars, that comply with Industry 4.0 standard.

GALLERIA

VIDEOS

CONTACTS

IKOI S.p.A.

Via Monte Verena, 20

Via Monte Verena, 20

36022 San Zeno di Cassola (VI) – Italy

Tel. +39 0424 259365

Fax +39 0424 570591

Web: www.ikoi.it

Mail: info@ikoi.it